This case study comes to us from Jeanette and her husband who were looking to install a wooden shed for storage at their school on behalf of Friends Of Grangefield School. They purchased a 10ft x 8ft shed from B&Q and began research for a suitable foundation that could be installed and be put to use immediately but without compromising on strength and other benefits.

Selecting a Plastic Shed Base

Installation Process

Jeanette and her husband began the installation as soon as possible. If you would like to find out how to install a Plastic Shed Base you can follow the steps and photos in this blog post.

Firstly, they measured out a 10ft x 8ft area in the designated area of the school and marked it out. From there a layer of grass and soil was excavated leaving a soil base.

On to the soil, a layer of small gravel was used in order to create a sub bas. This gravel was then leveled and compacted down as well as possible using a plank of wood to ensure it created a strong flat surface.

Next, they could install the Plastic Shed Base and Jeanette laid the base down 4 panels at a time and connected neighboring panels together using the specially designed slot and peg system. This process was repeated until the designated area was covered. This was completed quickly and easily.

Now Jeanette and her husband filled the installed base with the same gravel they used on the sub-base. This took very little time. Around 8kg of gravel or aggregate is needed to fill each panel so you can work out how much is needed for the entire area.

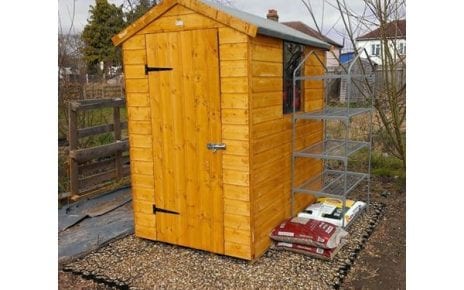

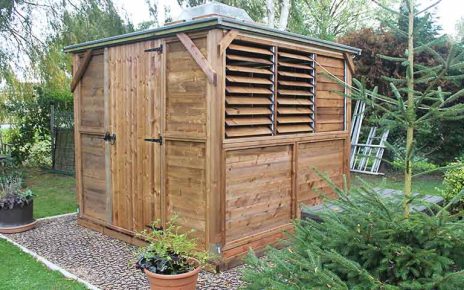

Finally, the shed was delivered and erected on the site so that they could start using it.

Conclusion

Jeanette is very happy with the final result and her shed will provide adequate storage and the base a strong foundation for many years to come.

Thank you to Jeanette and your husband for sharing your installation process of your Plastic Shed Base and allowing us to use your images to create this case study. If you have any photos of your installation or have any questions regarding our bases then please do not hesitate to contact us.

Need a Plastic Shed Base for your garden?

Hi me and wife has just got 25mtr allotment,how much cost for everything she’d and base say 10×6,

Hi John,

Thanks for your question. Here you can see our 10ft x 6ft plastic shed base kit, as for the shed it is difficult to say as it would depend on the type of shed you are wanting. You can see all of our garden sheds here.

Hope this helps, if you have any more questions please do not hesitate to get in touch.

The Garden Range